driven by

customer needs The strength to withstand the worst nature can produce while maintaining superior luxury and comfort – a stress-free sanctuary to protect you and your family.

Unrivalled quality every time with the stringent quality controls of factory produced components and on-site construction.

Technology to maintain the highest quality

Environmentally friendly sourcing of wood

Only the strongest, sustainably-sourced wood

Strong glue laminated wood requires strong source lumber.

One of the distinct features of SHAWOOD premium structural material is its strength, using high quality source wood.

This wood is most suitable for building material, having matured over 80-120 years in the optimum, cold climate to create tight growth rings.

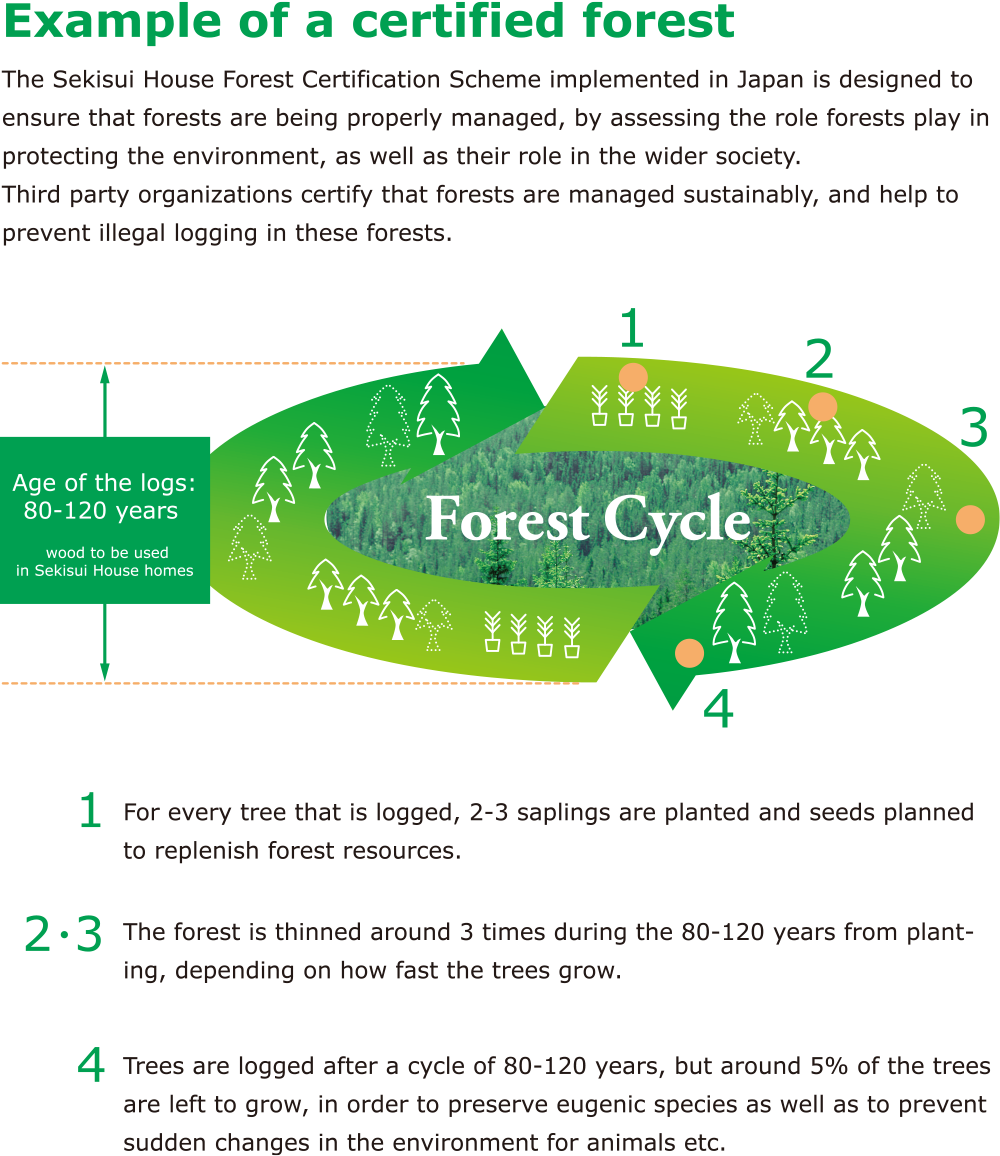

Concept of planting and planned logging in sustainable forests

Promoting sustainable sourcing of wood

Especially in Japan, Sekisui House has collaborated with environmentally-focused NGOs to create our own unique ethical and environmentally sensitive wood sourcing guidelines.

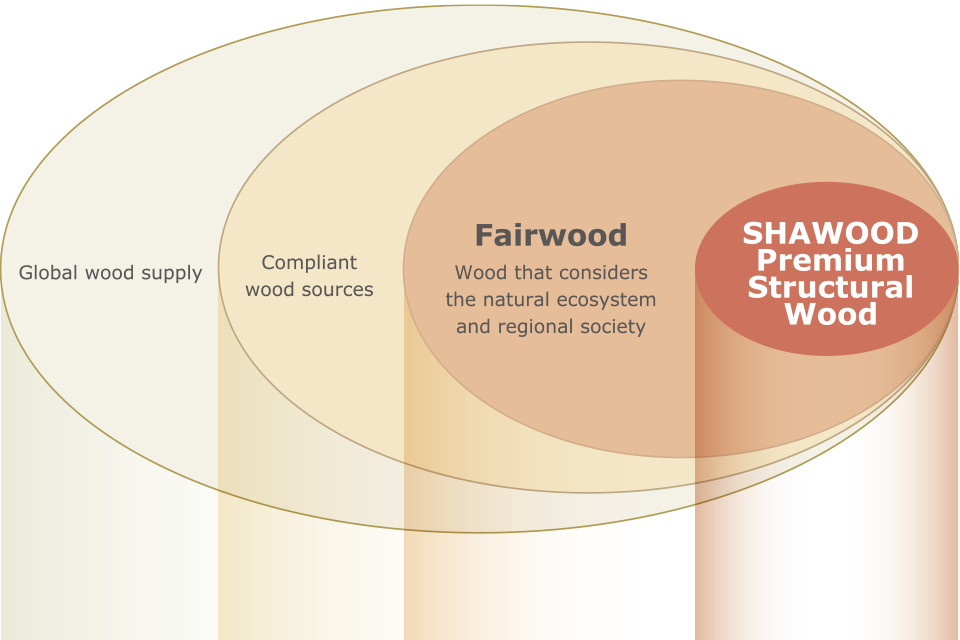

* In Japan, Sekisui House uses “Fair Wood”.

This is wood that considers the forest environment and local societies of its origins, such as forest-certified wood, wood that has not been logged illegally, or wood that comes from forests that the local residents are actively participating in maintaining.

Fair Wood is supported by the Global Environment Forum and international environment NGO FoE Japan.

Production and quality control

Structural wood tailor-made for each house

Each family has a different lifestyle. That is why SHAWOOD makes each beam for each house, with precision production, processing and shipment at our factory.

The materials are shipped to the worksite after pre-cutting and pre-setting of the metal joints, based on the design plans of each house, in order to minimize processing work at the construction site where various variables can arise.

In the pre-cutting process, each material is cut to the right size, together with high-precision cutting to make holes and slits for metal fittings.

Materials that have been pre-cut then have the metal fittings carefully pre-set.

As much as possible is done offsite before shipment, and then shipped out in accordance with the construction plans.

Our focus on tailor-made production and tailor-made shipment leads to high precision, improves the construction accuracy at the site, and also makes possible speedy construction.

Construction quality

Maintaining quality with thorough project management

One of the key features of our proprietary pre-engineered housing construction is that almost all components are manufactured offsite, leading to stable quality and accuracy and houses being able to achieve the performance as intended in the designs.

However, it is ultimately people that assemble these components on the build site to make a home, so we must ensure consistent workmanship, performance and quality of the home with workers of a wide variety of experience and expertise.

Sekisui House conducts meticulous construction quality control for each house built, continuous kaizen activities, as well as keeping track of and maintaining records of construction quality.